Debossing, custom packaging with printing

Do you know the printing technique that has existed for hundreds of years and is becoming more and more trendy? Get to know debossing, a 100% ecological printing technique. Also called letterpress, this technique is distinguished by its mechanical printing, and not digital, as it is widespread nowadays.

Used by our ancestors, it was used for a long time in the 19th century before being put aside the following century. It is in the 21st century that this printing returns to the taste of the day.

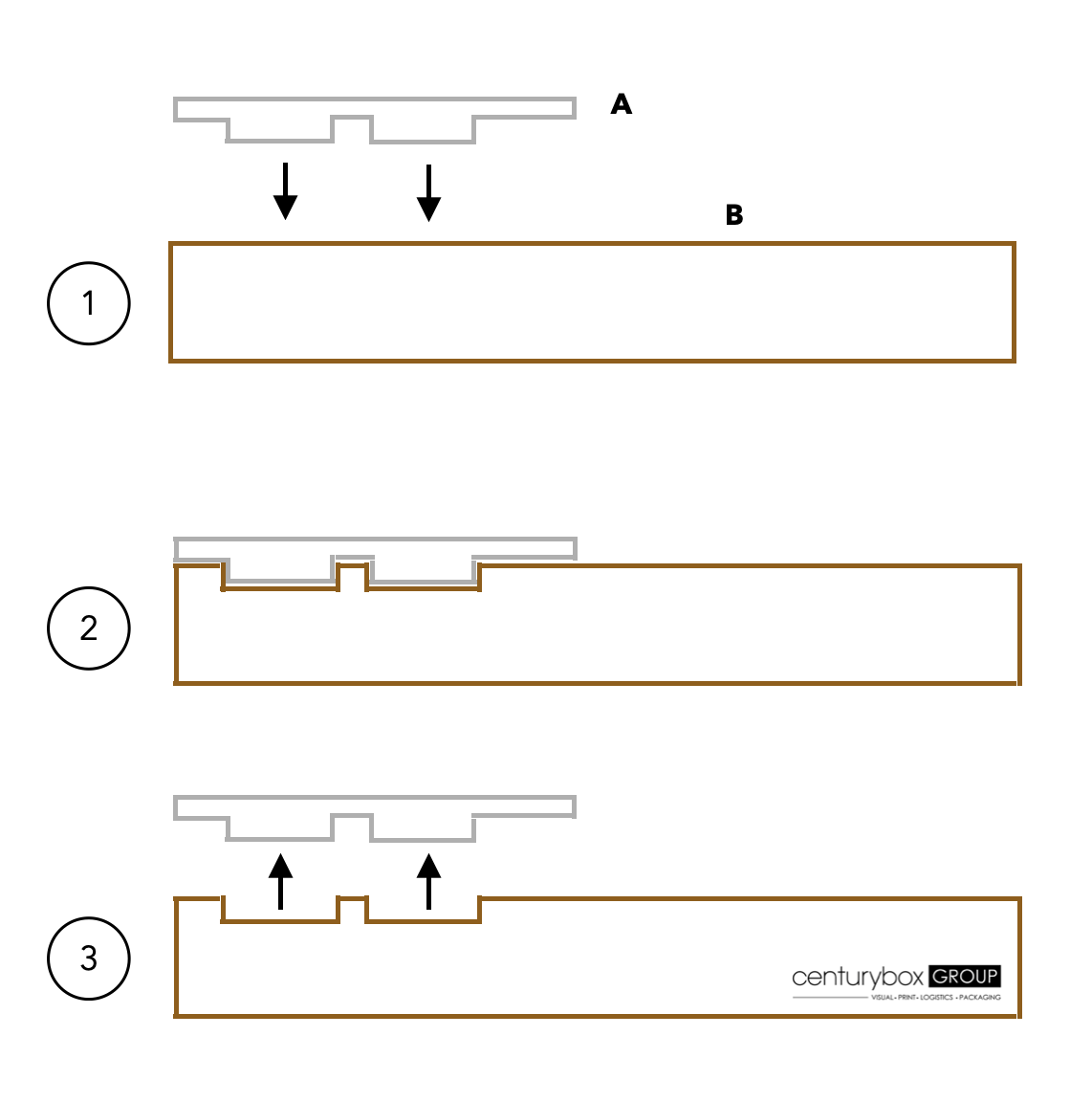

This printing technique is very simple to understand and has a particularity: no ink is used. How is it possible to see the result of the printing? Thanks to the relief that has been created. Indeed, no ink comes to fix itself on the paper or the cardboard, but rather a relief. This one results from the pressure of a magnesium plate (A), also called "cliché". This pressure will thus come to create a negative relief for the debossing or a positive relief for the embossing on the cardboard (B).

We therefore find ourselves with a marking that allows you to awaken two senses in your customers: sight and touch. This specificity is not negligible in a world where it is difficult to stand out. It is therefore not surprising to see many companies using this classy and ecological printing technique. Its luxurious and sober side does not indeed go unnoticed.

Embossing uses the same technique as hot stamping. The difference between these two techniques is the thin colored metallic film that is inserted between the surface to be printed and the plate for hot stamping. It is inserted between the two elements and is pressed onto the cardboard by the magnesium plate. Under the effect of heat, the film will stick to the wall while creating a slight negative relief. Without the metal film, only the negative relief will be present, which corresponds to the debossing. Find opposite an image illustrating the difference between hot stamping (above) and debossing (below).

At Centuryprint, you have the possibility to have your different packagings printed with these two types of printing. We carry out in our workshops of Villers-la-Ville the debossing for all the articles which allow the hot printing. Once you have selected your packaging, simply select "colorless embossing" as the printing color if you want a debossing. Our team will then carry out the printing with the magnesium plate, but without inserting the colored metallic film that hot stamping requires. We would be delighted to welcome you in our workshop to show you the process and the differences in printing. Do not hesitate to contact us by phone at +32 71 87 49 13 or by email info@centuryprint.eu

In addition, thanks to the largest packaging warehouse in Europe, which is located next to our offices, we will be able to respond to your needs in a shorter time frame than the average. Receive all your personalized orders within two weeks, starting at 50 units! Don't neglect the aesthetic aspect of your packaging, it is an integral part of the customer experience.

Discover the elegance and uniqueness of embossing for your custom packaging.

At Centuryprint, we offer an innovative approach to personalized packaging, where every detail is carefully considered. Embossing, a sophisticated marking technique, creates a remarkable visual impact by sculpting your logo or pattern onto the packaging.

This method adds a tactile and high-quality dimension to your bags and boxes, without the need for printing. With Centuryprint, your packaging becomes a true work of art, captivating the senses and leaving a memorable impression. Choose embossing for packaging that stands out with elegance and originality.

Share this content